Looking Back: Specialty Mfg. Co. Celebrates 120 Years of Manufacturing in the Custom Valve Industry

With a host of achievements to look back on, The Specialty Mfg. Co. is adding one more to the list by celebrating 120 years of service this September of 2020. A top manufacturer of custom and customized miniature valves, process control components, fixturing and pool components, Specialty Mfg. Co. (SMC) proudly serves a wide variety of industries across their home in the Midwest and beyond.

SAFEWAY JOINS ELITE TEAM TO SET STANDARDS FOR FLUID TRANSFER COMPONENTS.

Collaboration with industry leaders to set new standards for liquid cooling components means big opportunities for SafeWay. The OCP (Open Compute Project) is a nonprofit organization that shares designs and best practices for data center products and solutions. Among the group are leading computer hardware and software companies.

Industry’s Most Popular Suction Strainer Sizes Available As Fast As Next Day

Most quick-disconnect coupling manufacturers focus on offering standard products in dozens, if not hundreds of different sizes and types. Many times, off-the-shelf QDs work fine for a given task. They meet the necessary performance requirements and tend to offer ready availability and a reasonable price.

The benefits of custom quick disconnects

Most quick-disconnect coupling manufacturers focus on offering standard products in dozens, if not hundreds of different sizes and types. Many times, off-the-shelf QDs work fine for a given task. They meet the necessary performance requirements and tend to offer ready availability and a reasonable price.

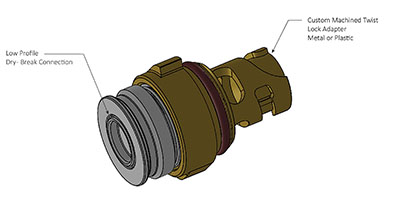

A Custom Coupler Solution for Electronics Cooling Applications

Simplifying assembly and installation with a dripless, easy and secure solution.

QuantaCool needed a unique refrigerant coupler to meet the demands of their new electronics cooling system. Off-the-shelf component options were too large and expensive, and other manufacturers…

Custom Coupler simplifies the lubrication and maintenance for track tensioning system

Time is money when managing routine maintenance and lubrication of drive tracks on excavating equipment. Efficiency of the filling and flushing of the lubricants that optimize equipment uptime is vital.