Specialty Manufacturing company’s vertical integration combines engineering, advanced metal machining, plastic injection molding, grinding, stamping and assembly capabilities under one roof. Along with over 100 years of expertise to assure that optimized manufacturing is integral to every product we make. Reducing overall costs and lead times help take the worry out of the most challenging projects. We have the experience to take on the manufacturing challenges that our competitors can’t or won’t attempt.

Partnered with parent company The Specialty Manufacturing Co., SafeWay strives to continuously innovate our manufacturing capabilities, while tailoring our services to the varied needs of our customers. We are proud of the custom and ISO standard solutions we provide for industry leaders in agriculture, electronics, manufacturing and much more. As ISO standard and custom coupling manufacturers, we are willing to work with our customers to explore and execute unique solutions that leverage the use of plastic and metal materials, and varied finishing methods, such as hardening, annealing and various coatings.

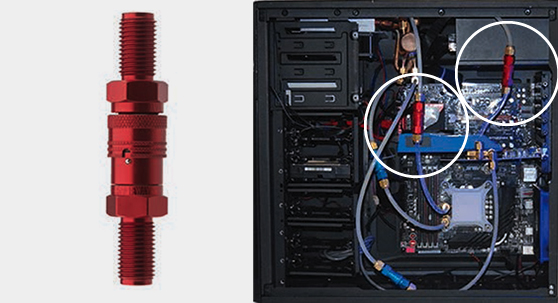

Reliable, Quick and Easy Modular Design When a new customer came to us in need of a fluid transfer coupling solution for cooling within electronics enclosures, we met the challenge head on. In this unique case, off-the-shelf couplers were too large and heavy for the confined space of their products. SafeWay engineers recommended reducing the

Simplifies Lubrication, and Maintenance Time is money when managing routine maintenance and lubrication of drive tracks on excavating equipment. A leading excavation machinery manufacturer designed a single zerk hydraulic system to deliver and bleed grease used to set/adjust track tension on their equipment. The system required a reliable and durable mechanism to inject lubricant, and

Eliminates Errors and Streamlines Changeover When a leading manufacturer of high-performance lubricants needed to be certain workers could quickly and easily distinguish among their fluid lines’ many standard quick disconnects, the production workers sometimes made costly connection errors that cross contaminated fluids. The lubricant manufacturer turned to SafeWay for a solution to their error-prone fluid-transfer